Liquid Crystal Display (LCD) is a kind of Flat Panel Display technology (FPD), based on the special physicochemical and photoelectric properties of liquid crystal materials, is currently the most mature and widely used display device in flat panel display technology. Mainly used in TV, monitor, notebook computer, tablet computer, smart phone and other fields.

At present, the so-called LCD on the market mainly refers to the active matrix Thin Film Transistor LCD (TFT-LCD), including the thin film transistor (TFT) and liquid crystal display (LCD) two technologies, that is, the liquid crystal display controlled by the thin film transistor.

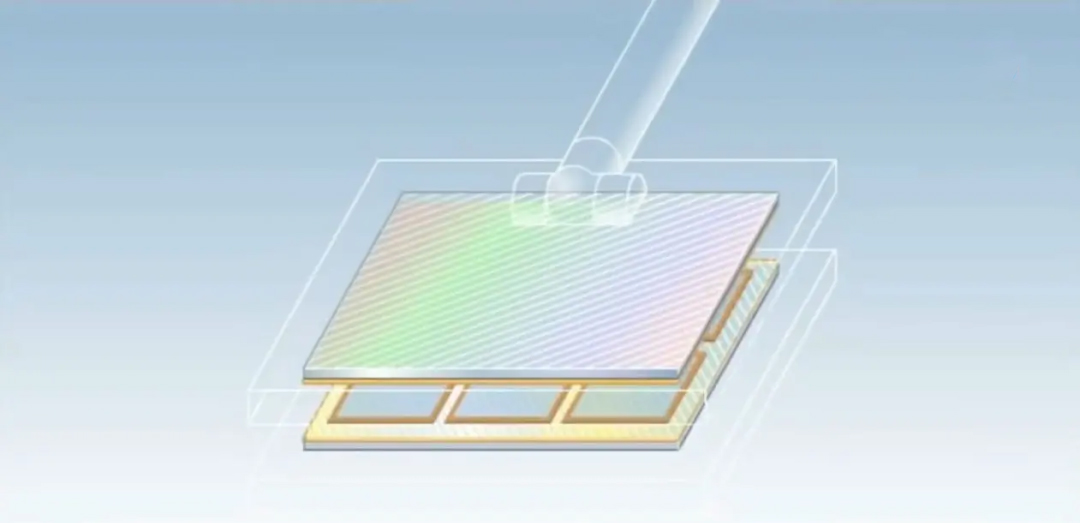

TFT-LCD: Sandwich like structure

The structure of the LCD screen is like a sandwich, and the liquid crystal is intermixed between two glass substrates, which are TFT Array glass and colored filters. There are countless pixels arranged on the TFT Array glass, and the color filter is an important source of the color of the picture, and the liquid crystal is intermingled between the TFT Array and the color filter.

When the voltage is at the TFT(transistor), the liquid crystal turns, and the light passes through the liquid crystal to produce a pixel on the panel, and this light source is provided by the backlight module. At this point, the colored filter gives each element a specific color. The combination of each of the different colors creates an image of the front of the panel.

TFT-LCD must be produced in a precision clean room after more than 300 processes. The cleanroom can have a maximum cleanliness rating of "10" (i.e., only 10 dust particles per cubic foot within the cleanroom environment).

TFT-LCD main three stage process

Front Array

The previous part of the Array process is similar to the semiconductor process, but the difference is that the thin film transistor is made on the glass, rather than on the silicon wafer.

The middle part of the Cell is based on the TFT Array glass in the front segment as the substrate, combined with the colored filter glass substrate, and the liquid crystal is dropped between the two glass substrates and then bonded, and then the large piece of glass is cut into a panel.

The assembly process of the latter part of the module is the assembly and production of the glass after the Cell process and other parts such as the circuit, the outer frame, the backlight plate and so on.

TFT-LCD factory - generation and size

The factory of TFT-LCD has evolved from the former generation 1 factory to the current generation 11 factory, and the difference between the plants of each generation is the size of the glass substrate. The larger the glass substrate, the larger size of the panel can be cut.